Introduction to Soft Magnets

Soft magnetic materials are those materials that are easily magnetised and demagnetised. They typically have intrinsic coercivity less than 1000 Am-1. They are used primarily to enhance and/or channel the flux produced by an electric current.

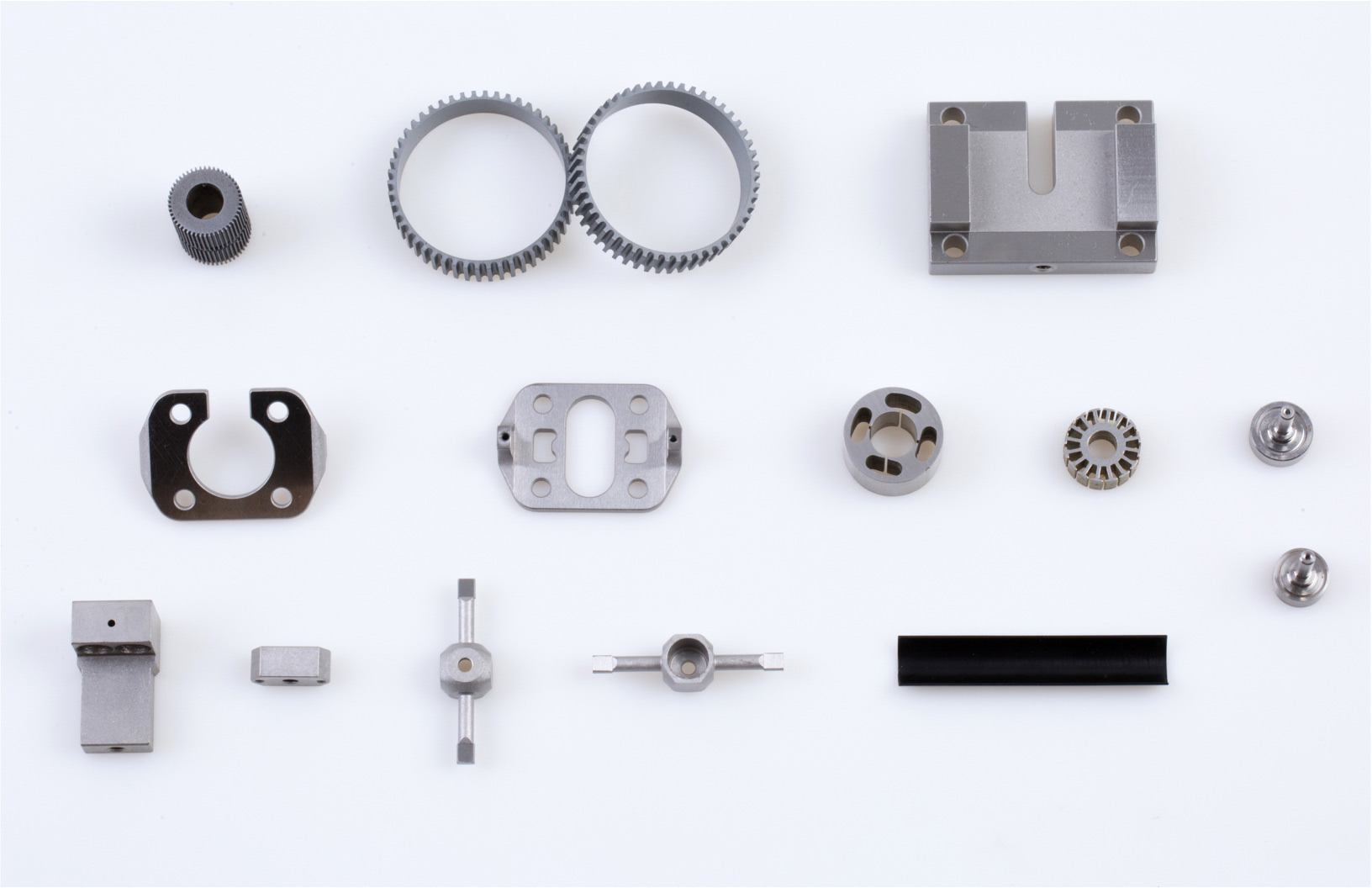

Soft magnetic materials are mainly used in generators, transformers, motors, coils, antennas, switches, etc.

ESSEN now offers:

- Iron-Silicon Alloys

- Iron-Cobalt Alloys

- Nickel-Iron Alloys

- Soft Ferrites

Typical Magnetic Properties of Soft Magnets

| FeCoV Soft Magnetics Alloy | ||||||||

|---|---|---|---|---|---|---|---|---|

| Magnetic Induction | Coercive Force | |||||||

| Grade | Level | B400 | B800 | B1600 | B2400 | B4000 | B8000 | Hc |

| T(Min) | A/m(Max) | |||||||

| 1J21 | I | 1.8 | 2 | 2.1 | 2.3 | 2.4 | – | 80 |

| II | 1.8 | 2 | 2.1 | 2.3 | 2.4 | – | 48 | |

| 1J22 | – | 1.6 | 1.8 | 2 | 2.1 | 2.2 | 2.2 | 128 |

| FeCoV Magnetic Hysteresis Alloy | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | Semi-processed | Level | B(m) ±1.23T | B(m) ±1.36T | B(m) ±1.42T | |||

| Hm | Pro(105erg/cm3Hz) | Hm | Pro(105erg/cm3Hz) | Hm | Pro(105erg/cm3Hz) | |||

| (A/m) | – | (A/m) | – | (A/m) | – | |||

| 2J4 | Cold rolled strip | II | ≤4400 | ≥1.44 | ≤4800 | ≥1.65 | ≤5200 | ≥1.85 |

| Measured in magnetic field | Measured in magnetic field | |||||||

| 5174 A/m | 9552 A/m | |||||||

| Br | Hc | Pro(105erg/cm3Hz) | Br | Hc | Pro(105erg/cm3Hz) | |||

| (T) | (A/m) | – | (T) | (A/m) | – | |||

| ≥1.1 | ≥3582 | ≥1.8 | ≥1.1 | ≥3582 | ≥2.6 | |||

| FeNi Soft Magnetic Alloy | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | Semi-processed | Level | Thickness/Diameter | U0.4 | Um | Hc | Bs | |

| – | – | mm | mH/m(min) | A/m(max) | T(min) | |||

| IJ50 | Cold rolled Strip | II | 0.10-0.19 | 3.8 | 43.8 | 12 | 12 | 15 |

| 0.20-0.34 | 4.4 | 56.3 | 10.4 | 10.4 | 15 | |||

| 0.35-0.50 | 5 | 6.5 | 8.8 | 8.8 | 15 | |||

| 0.51-1.00 | 5 | 50 | 10 | 10 | 15 | |||

| 1.10-2.50 | 3.8 | 44 | 12 | 12 | 15 | |||

| IJ85 | Cold rolled Strip | II | 0.20-0.34 | 50 | 225 | 1.2 | 1.2 | 0.7 |

| 0.35-1.00 | 62.5 | 312.5 | 0.8 | 0.8 | 0.7 | |||

| 1.10-2.50 | 50 | 50 | 1.2 | 1.2 | 0.7 | |||

| 2.51-3.00 | 43.8 | 43.8 | 1.4 | 1.4 | 0.7 | |||

| Anti-corrosion Soft Magnetic Alloy | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | Magnetic Induction | Remanence Induction | Um | Hc | ||||

| B240 | B400 | B800 | B2400 | B3200 | B3200 | – | – | |

| T(min) | T(max) | mH/m(min) | A/m(max) | |||||

| 1J117 | 0.9 | – | 1 | – | 1.25 | – | – | 80 |

| Cr17NiTi | – | 0.9 | 1 | 1.2 | – | 0.95 | 3.75 | 80 |

Soft Magnets Materials

Soft magnetic materials are those materials that are easily magnetised and demagnetised. They typically have intrinsic coercivity less than 1000 Am-1. They are used primarily to enhance and/or channel the flux produced by an electric current. The main parameter, often used as a figure of merit for soft magnetic materials, is the relative permeability (µr, where µr = B/ µoH), which is a measure of how readily the material responds to the applied magnetic field. The other main parameters of interest are the coercivity, the saturation magnetization, and the electrical conductivity. The types of applications for soft magnetic materials fall into two main categories: AC and DC.

In DC applications the material is magnetized in order to perform an operation and then demagnetized at the conclusion of the operation, e.g. an electromagnet on a crane at a scrap yard will be switched on to attract the scrap steel and then switched off to drop the steel.

In AC applications the material will be continuously cycled from being magnetized in one direction to the other, throughout the period of operation, e.g. a power supply transformer. A high permeability will be desirable for each type of application but the significance of the other properties varies.

For DC applications the main consideration for material selection is most likely to be permeability. This would be the case, for example, in shielding applications where the flux must be channeled through the material. Where the material is used to generate a magnetic field or to create a force then the saturation magnetization may also be significant.

Types of Soft Magnets

These alloys are used for transformer cores and are known as electrical steels. In the power industry electrical voltage is almost always AC and at low frequency, 50-60Hz. At these frequencies, eddy currents are generated in the transformer core. Alloying the Fe with Si has a large marked effect on the electric resistivity of the material, with an increase of a factor of 4 for 3wt%Si.

Silicon also has the benefit of reducing the magnetostriction (i.e. length change on magnetization) and the magnetocrystalline anisotropy. In addition, the material is used in the form of laminations, typically 0.3 to 0.7mm thick.

Cobalt-based soft magnet alloys have advantages over other soft magnets in that they have a high saturation point, have a good permeability in magnetic fields, and have a high Curie Point of 950-990oC resulting in magnetic properties not being altered under temperatures of 500oC.

These alloys, known as permalloy, are extremely versatile and are used over a wide range of compositions, from 30 to 80wt%Ni. Over this composition range, the properties vary and the optimum composition must be selected for a particular application.

At high frequency metallic soft magnetic materials simply cannot be used due to the eddy current losses. Therefore, soft ferrites, which are ceramic insulators, become the most desirable material.

These materials are ferrimagnetic with a cubic crystal structure and the general composition MO.Fe2O3, where M is a transition metal such as nickel, manganese, or zinc.