Magnetic Assembly

Permanent Lifting Magnets

A Lifting Magnet is a magnetic device specifically designed to lift, move, and transport heavy ferrous (iron-containing) materials, such as steel plates, beams, or pipes. It uses magnetic force to securely grip the material, allowing it to be lifted and positioned without the need for clamps, hooks, or slings. Lifting magnets are commonly used in industries like construction, manufacturing, and material handling.

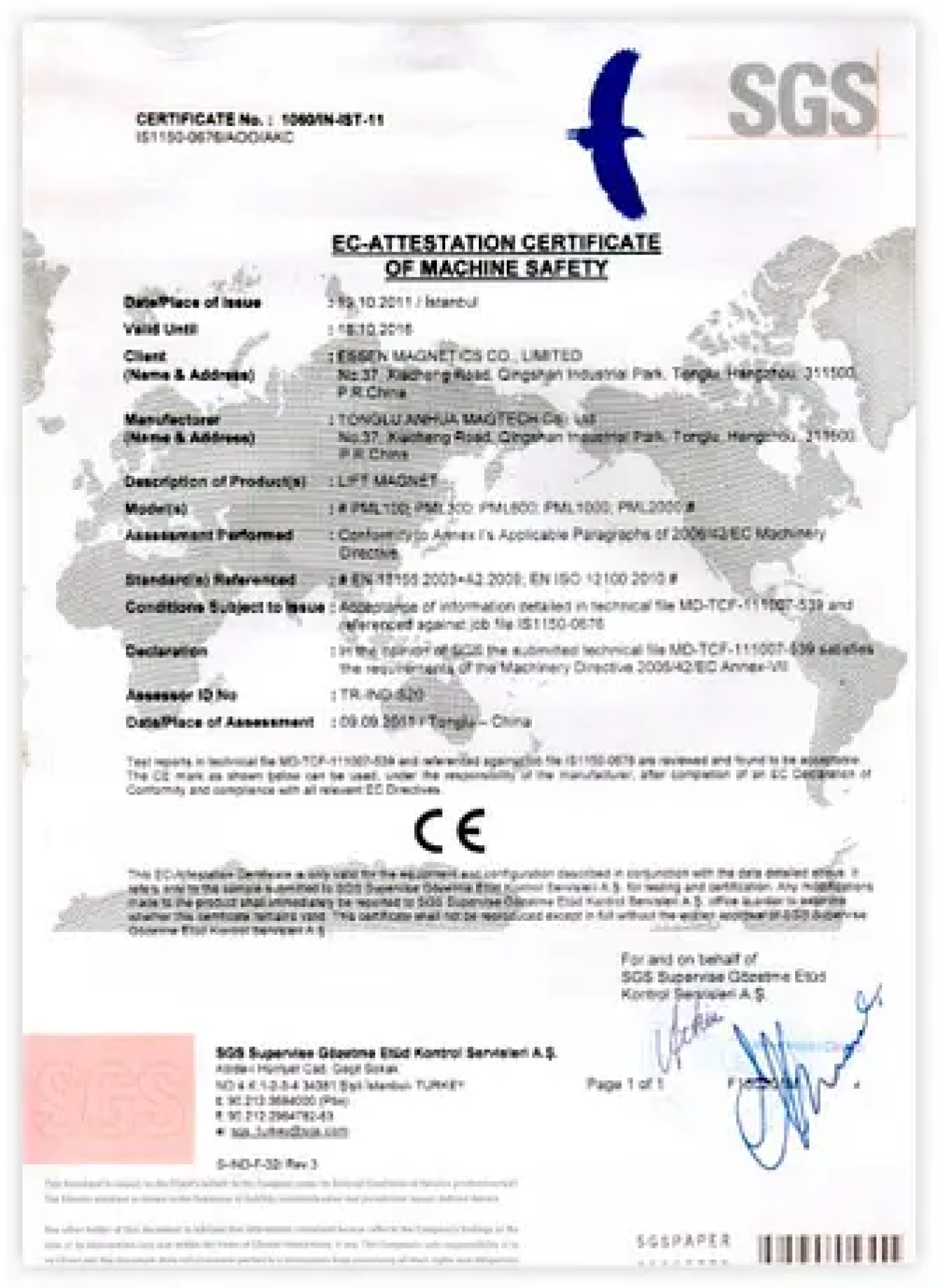

ESSEN now has a specialized production line for permanent lifting magnets, with an annual output exceeding 10,000 units. The company's products have passed SGS CE safety certification. All lifting magnets are covered by China Ping An Insurance's product liability insurance.

Key Features

Powerful Holding Force

Essen Lifting magnets are designed to hold and lift very heavy objects with strong holding force.

Safety Features

Essen lifting magnets include built-in safety locks / mechanisms to prevent accidental release of the load. Each lifting magnet is 3.5 times rated capacity factor of safety.

Ease of Use

Simplify material handling by eliminating the need for complicated rigging or mechanical fasteners, and also no need for electricity.

Common Applications

Moving steel plates, beams, and bars in warehouses or construction sites.

Handling ferrous materials in manufacturing, shipbuilding, and automotive industries.

Lifting and positioning machinery parts or large metal components in workshops or factories.

We are selling only certified Permanent Lifting Magnets

Our permanent lifting magnets are tested in the SGS-CSTC in Shanghai Lab.

Individually Tested

Each magnet is individually tested before goes out, including a certificate of the capacity.

Machinery Directive

Each permanent lifting magnet meets the requirements of the Machinery Directive of European Parliament and European Council 2006/42/EC Annex-VII.

3.5 Times Rated

Each permanent lifting magnets is 3.5 times rated capacity factor of safety and meets ASME B30.20 SAFTY STANDARDS

Neodymium (Neo) Pot Magnets

A neodymium pot magnet, is a type of powerful magnetic device that utilizes a neodymium magnet encased in a steel pot or housing. These magnets are commonly used in industrial and commercial applications due to their strong magnetic force and durability.

ESSEN supplies different styles of Neo pot magnets in a variety of stock dimensions as below:

Round Base Magnets

A round base magnet / cup magnet is a type of magnet encased in a steel shell or cup, which enhances its magnetic strength by concentrating the magnetic field at its face. The round base design allows it to have a flat surface on one side, while the other side is either fitted with a screw hole, hook, or other mounting feature.

These magnets are commonly used in industrial, commercial, and DIY applications for holding, mounting, lifting, and retrieving metal objects. The steel casing protects the magnet from damage and directs its magnetic force toward the base, making it more efficient.

ESSEN offers steel cup round magnetic base assemblies in a range of standard dimensions, featuring either ceramic or neodymium magnets. If the size you need is not listed below, we can also provide custom steel cup assemblies tailored to your exact specifications.

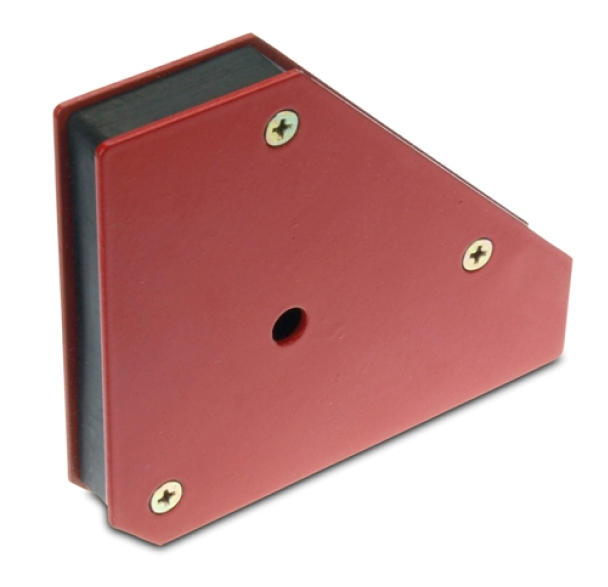

Work Holding Magnets

Work holding magnets are specialized magnetic devices designed to securely hold or position metal workpieces during manufacturing processes, such as welding, drilling, machining, cutting, or assembly. These magnets provide a fast, reliable, and convenient method for clamping ferrous materials, eliminating the need for traditional mechanical clamps.

ESSEN now can provide on/off work holding magnets with 70kg - 450 kg holding capacity. For use in welding, woodworking or anywhere steel is used. The magnets exert a strong magnetic hold on 3 sides, and provide fast and easy multi-plane work holding for positioning steel. They are ideal for fixturing and offer many uses: level sheet, support, stop, guide, mounting base; the uses are endless. A must for every fabricator and welder.

Neodymium Rectangular Magnet with Countersunk Holes( Channel Magnet)

Neodymium Rectangular Magnet with Countersunk Holes (Channel Magnet) is a type of magnetic assembly where a strong neodymium magnet, is encased in a U-shaped steel channel or housing. This design focuses and directs the magnetic force, making the magnet significantly stronger than a regular magnet of the same size. Channel magnets are widely used in holding, mounting, and assembly applications where strong magnetic force is required in a compact form factor.

Common Applications of Channel Magnets

Mounting and Holding

Channel magnets are widely used in mounting applications where a strong and stable magnetic hold is necessary. For instance, they can be mounted to walls or workbenches to hold tools, fixtures, signage, or display materials. In retail and industrial settings, they are used to hold parts, equipment, or shelves in place.

Fixture Positioning

These magnets are used in fabrication and assembly processes to hold workpieces, jigs, or fixtures securely in place. Their focused magnetic field ensures that metal parts stay aligned and fixed during welding, cutting, or machining operations.

Workshop Tool Holder

Channel magnets can be mounted on the wall of a workshop to hold metal tools, making them easy to access and organize.

Cabinet Door Closure

A channel magnet can be installed inside a cabinet or drawer as a magnetic latch, providing a simple and clean solution for keeping doors closed. Fixture in Welding Operations: During metal fabrication, a channel magnet can be used to hold metal pieces together temporarily, allowing the welder to focus on the task.

Essen can offer below channel magnets, custom types and sizes are also available upon request.

Halbach Array

Halbach Array is a special arrangement of permanent magnets that enhances the magnetic field on one side of the array while reducing it on the other. This results in a strong, concentrated magnetic field on the "active" side and a weaker or nearly negligible field on the opposite side. The key to this arrangement lies in how the magnets are oriented, with their magnetic poles alternating in a specific pattern.

Key Features of a Halbach Array

Magnetic Field Enhancement

On one side of the array, the magnetic field is significantly stronger than it would be for the same magnets in a simpler arrangement.

Magnetic Field Cancellation

On the opposite side, the field is minimized or nearly canceled out.

Efficient Use of Magnets

By concentrating the field in one direction, Halbach arrays make more efficient use of magnetic material, improving the overall performance of devices using them.

Applications

The Halbach array is an elegant solution for generating directional magnetic fields without the need for electromagnets, making it useful in various advanced technologies.

Magnetic levitation

On one side of the array, the magnetic field is significantly stronger than it would be for the same magnets in a simpler arrangement.

Magnetic Field Cancellation

On the opposite side, the field is minimized or nearly canceled out.

Efficient Use of Magnets

By concentrating the field in one direction, Halbach arrays make more efficient use of magnetic material, improving the overall performance of devices using them.

Linear Halbach arrays

A linear Halbach array is a specific type of Halbach array in which permanent magnets are arranged in a straight line rather than in a circular or cylindrical configuration. Just like the general Halbach array, this linear version enhances the magnetic field on one side of the array while reducing it on the other. The magnets are oriented with alternating poles in such a way that their fields constructively interfere on one side and destructively interfere on the other.

Halbach cylinder

A Halbach cylinder is a powerful and elegant magnetic structure that takes advantage of a clever arrangement of permanent magnets to create a strong, focused magnetic field in a specific region while suppressing the field in others. The cylinder form offers distinct advantages over linear or rectangular Halbach arrays because of its symmetry, allowing for applications that require cylindrical or radial magnetic fields.

Other Magnetic Assemblies

Since 2003, ESSEN Magnetics has provided in-house manufacturing expertise to transform your designs and specifications into custom-engineered magnetic assemblies or magnets, from concept to production. From rapid prototypes to large-scale production, we have the equipment, technical expertise, strong partnerships with key suppliers, and skilled personnel to meet your unique application needs.

Partner with Custom Magnet and Magnetic Assembly Experts

Our engineering team thrives on solving tough challenges, ensuring our customers’ magnetic assemblies meet performance requirements. We know that a successful magnetic assembly requires the perfect combination of magnetic materials, steel, epoxy, placement, dimensions, tolerances, and focused magnetic fields. This is why clients rely on our technical and manufacturing capabilities time after time.

For high-volume orders, we’ve developed efficient assembly processes, specialized tooling, and rigorous quality systems to control costs and ensure timely delivery. Our production team is experienced in implementing automation systems where possible and designing custom automation equipment for quick scaling.

ESSEN Magnetics has created magnetic assemblies for industries such as medical devices, motors, mining, consumer electronics, and more. With ISO-certified facilities, we’ve become a trusted one-stop resource for custom magnetic solutions.